Description

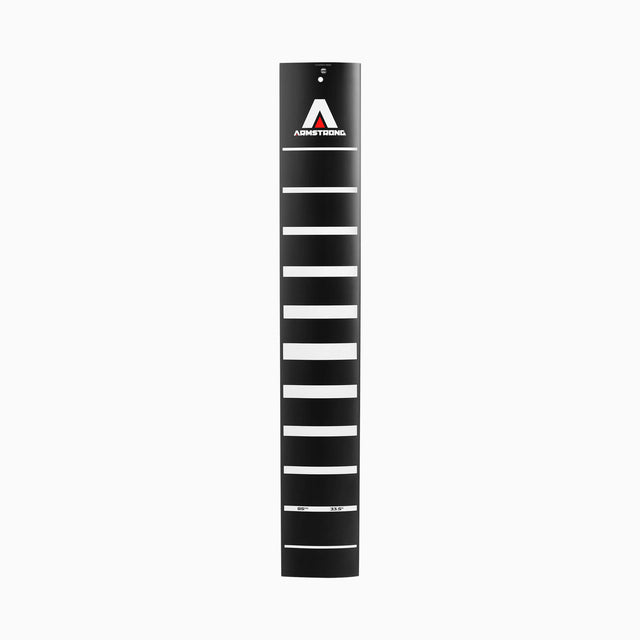

Armstrong Alloy Mast: Durable, Reliable, and Performance-Driven

The Armstrong Alloy Mast stands as a robust, dependable choice for foilers who demand both strength and value. Designed for riders who want a mast that balances durability with affordability, this mast delivers performance across a variety of conditions without sacrificing essential quality.

Superior Material Composition for Strength and Longevity

Armstrong’s Alloy Mast utilizes high-grade aluminum alloy specifically selected to withstand the rigors of foiling. Unlike standard aluminum masts, Armstrong applies advanced heat treatments and anodizing processes, which enhance corrosion resistance and structural integrity.

Consequently, the mast resists saltwater corrosion far better than untreated metals. This durability makes it an excellent option for riders who seek a mast that requires less maintenance but still holds up in challenging environments.

Precision Engineering and Manufacturing

Armstrong combines modern CNC machining with strict quality control standards. Each alloy mast is crafted with precision to exact specifications, ensuring consistent performance across the production line.

Additionally, the surface finish undergoes a multi-step anodizing process, not only protecting the mast but also providing a sleek, professional appearance. This attention to detail reflects Armstrong’s commitment to quality, even in their alloy range.

Performance Benefits That Meet Every Rider’s Needs

Despite alloy being heavier than carbon fiber, the Armstrong Alloy Mast offers impressive strength and stiffness. This rigidity translates to excellent control and stability during rides, especially in rough water or high-speed scenarios.

Moreover, many riders appreciate the slightly higher flex of alloy masts compared to carbon, which some find more forgiving and comfortable. This characteristic makes the Armstrong Alloy Mast ideal for beginners and intermediate riders who prioritize a smooth, responsive ride.

Compatibility and Versatility

The Armstrong Alloy Mast features standardized mounting points compatible with most foil boards and systems on the market. This flexibility allows riders to upgrade or swap components without hassle.

Whether you’re starting fresh or replacing an older mast, the Armstrong Alloy Mast integrates seamlessly into your setup.armstrong mixture

Technical Specifications of the Armstrong Alloy Mast

Understanding the technical specifications of the Armstrong Alloy Mast is essential for riders who demand reliable and consistent performance. These detailed specs highlight the mast’s robust construction and compatibility with a broad range of foiling setups.

High-Grade Aluminum Alloy Construction

First and foremost, the Armstrong Alloy Mast is constructed from a premium aluminum alloy known for its outstanding strength-to-weight ratio. This alloy undergoes advanced heat treatment and anodizing processes, which significantly increase corrosion resistance and surface hardness.

As a result, the mast can endure the harsh conditions commonly encountered during foiling, such as saltwater exposure, UV radiation, and mechanical stresses, without degradation over time.armstrong mixture

Dimensions and Weight Variations

The Armstrong Alloy Mast is offered in several standard lengths, typically including 70 cm, 80 cm, and 90 cm options. This variety allows riders to select the mast size that best suits their riding style and typical water conditions.

Furthermore, the mast’s diameter is engineered to optimize stiffness while minimizing drag. With a weight ranging between approximately 1.8 and 2.4 kilograms depending on size, it strikes a balance between durability and manageable handling.armstrong mixture

Load Capacity and Structural Integrity

Additionally, the alloy mast undergoes rigorous mechanical testing to ensure it meets stringent load-bearing requirements. Tests confirm the mast’s ability to withstand bending and torsional forces well beyond what typical foiling maneuvers demand.

Consequently, riders can trust the Armstrong Alloy Mast to deliver consistent performance without fear of structural failure, even during aggressive or high-impact sessions.armstrong mixture

Compatibility with Foil and Board Systems

Moreover, Armstrong designed the Alloy Mast to be fully compatible with major foil and board mounting systems. Standardized fittings such as Tuttle boxes and plate mounts allow easy integration with existing equipment.

Therefore, whether upgrading or assembling a new setup, the Armstrong Alloy Mast fits seamlessly into your gear, eliminating compatibility concerns.armstrong mixture

Surface Finish and Protective Coating

Finally, the mast’s surface is treated with a multi-layer anodized coating that enhances resistance to scratches and environmental damage. This finish not only prolongs the mast’s lifespan but also offers a sleek, professional aesthetic.armstrong mixture

Summary of Key Technical Specifications

| Specification | Details |

|---|---|

| Material | High-grade aluminum alloy with anodized finish |

| Length Options | 70 cm, 80 cm, 90 cm |

| Weight | Approximately 1.8 – 2.4 kg (size-dependent) |

| Diameter | Optimized for stiffness and low drag |

| Load Capacity | Tested for high bending and torsion resistance |

| Mount Compatibility | Tuttle box, plate mounts, standard foil systems |

| Surface Finish | Multi-layer anodized protective coating |

sup downwind hydrofoil Why These Specifications Matter

To sum up, these technical attributes combine to make the Armstrong Alloy Mast a dependable, high-quality choice. Whether you are a beginner seeking durability or an experienced rider wanting consistent performance, this mast delivers.

Its construction ensures resistance to environmental wear while maintaining manageable weight and stiffness. Furthermore, compatibility across various systems simplifies installation and upgrades.sup downwind hydrofoil

Manufacturing Process and Quality Control of the Armstrong Alloy Mast

The remarkable performance of the Armstrong Alloy Mast is the direct result of a carefully controlled manufacturing process combined with rigorous quality assurance. Armstrong’s commitment to excellence ensures that every mast leaving the factory meets the highest standards of durability, precision, and reliability.armstrong mixture

Precision Alloy Selection and Treatment

Initially, Armstrong sources high-quality aluminum alloy, chosen for its exceptional strength-to-weight ratio and corrosion resistance. This material undergoes precise heat treatment processes, including solution treating and aging, which enhance its mechanical properties.armstrong mixture

Consequently, these treatments improve tensile strength and hardness, allowing the mast to resist deformation and wear over time, even under intense usage.armstrong mixture

CNC Machining and Component Fabrication

After alloy treatment, the mast components are crafted using advanced CNC machining technology. This method guarantees tight tolerances and exact dimensions, critical for ensuring proper fit and consistent performance.

Moreover, CNC machining reduces material waste and produces a superior surface finish, which serves as the foundation for subsequent protective coatings.

Multi-Step Anodizing and Protective Finishing

The machined mast then receives a multi-layer anodized coating. This electrochemical process builds a hard, corrosion-resistant layer on the aluminum surface. Furthermore, it enhances scratch resistance and UV protection, helping the mast maintain its appearance and structural integrity over prolonged exposure to marine environments.

In addition, the anodizing process allows for customization in color and finish, which can reflect Armstrong’s signature aesthetics.sup downwind hydrofoil

Comprehensive Quality Control Procedures

Every Armstrong Alloy Mast undergoes stringent quality control inspections throughout production. These include dimensional verification, surface finish assessments, and mechanical testing to confirm load-bearing capabilities.

Moreover, batch traceability is maintained through serial numbering, ensuring accountability and facilitating warranty services if needed.sup downwind hydrofoil

Continuous Improvement Through Feedback

Armstrong actively incorporates feedback from athletes, technicians, and dealers to refine manufacturing techniques and quality standards. This iterative process ensures that each new batch of Alloy Masts benefits from the latest innovations and user-driven improvements.sup downwind hydrofoil

Why Quality Control Is Essential

Ultimately, this detailed manufacturing and quality control approach guarantees that the Armstrong Alloy Mast performs consistently and safely. It minimizes defects and maximizes product lifespan, giving riders confidence in their investment.

Armstrong’s dedication to precision and quality supports a mast that can handle the toughest conditions while delivering reliable, high-level performance.

Performance Benefits of the Armstrong Alloy Mast

The Armstrong Alloy Mast delivers a combination of strength, durability, and responsive handling that suits a wide range of foiling riders. Engineered to withstand demanding conditions, this mast provides riders with confidence and control on every session.

Exceptional Strength and Durability

Primarily, the alloy mast’s robust aluminum construction ensures it withstands high loads and impacts. Thanks to Armstrong’s advanced heat treatments and precise manufacturing, the mast resists bending, torsion, and fatigue even under intense use.

Moreover, the multi-layer anodized finish protects against corrosion, abrasion, and UV damage. Therefore, the mast maintains its structural integrity and aesthetic appeal over long periods, reducing the need for frequent replacements.

Balanced Flexibility for Responsive Control

Unlike some stiffer carbon counterparts, the Armstrong Alloy Mast offers a balanced flex pattern. This flexibility absorbs shocks from choppy water and rough landings, providing a smoother and more comfortable ride.

Consequently, many riders find this flex enhances board control, especially during carving and aggressive maneuvers. The responsive feel improves rider confidence, which is particularly beneficial for beginners and intermediates progressing their skills.

Reliable Performance Across Conditions

In addition, the Armstrong Alloy Mast performs reliably in various water conditions—from flat lakes to coastal waves. Its robust build and corrosion resistance make it suitable for both freshwater and saltwater environments.

This versatility allows riders to enjoy consistent performance without worrying about environmental wear or sudden failures.

Compatibility and Ease of Use

Furthermore, the mast’s design supports quick and secure mounting with most foil boards and systems. This ease of installation makes upgrading or replacing your mast hassle-free, saving valuable time and effort.

The solid connection between mast and foil translates to stable, predictable handling, essential for achieving high performance on the water.

Endorsements from the Foiling Community

Numerous riders and coaches endorse the Armstrong Alloy Mast for its durability and ride quality. Testimonials often emphasize its reliability during intense training sessions and competitions.

One experienced rider noted, “The Armstrong Alloy Mast strikes the perfect balance between strength and flex. It holds up under pressure while giving me the control I need for technical maneuvers.”

Key Performance Highlights

-

Robust aluminum construction offers exceptional strength and impact resistance

-

Multi-layer anodized finish enhances corrosion and abrasion protection

-

Balanced flex absorbs shocks, improving comfort and control

-

Consistent performance across freshwater and saltwater conditions

-

Easy compatibility with major foil systems for seamless integration

User Experience and Testimonials: What Riders Say About the Armstrong Alloy Mast

The true measure of any product lies in the feedback from those who use it daily. The Armstrong Alloy Mast consistently earns high praise from a diverse range of foilers—from beginners learning the ropes to seasoned pros pushing their limits.

Professional Riders Highlight Reliability and Control

Elite athletes value the mast’s blend of strength and responsive flex. For instance, competitive rider Jason Mitchell remarked, “The Armstrong Alloy Mast delivers rock-solid stability while maintaining the right amount of flex to absorb rough landings. It’s become my go-to mast for training and racing.”

These endorsements underline the mast’s ability to handle high-performance demands without compromising durability.

Beginners Appreciate Durability and Forgiveness

Many novice riders highlight how the alloy mast’s forgiving flex and sturdy build help them progress faster. Sarah K., a passionate beginner, shared, “I’ve crashed a few times, but the mast held up perfectly. Its slight flex gives me confidence when I’m still finding my balance.”

This combination of toughness and user-friendly performance makes the Armstrong Alloy Mast an ideal choice for those new to foiling.

Long-Term Users Praise Longevity and Low Maintenance

Long-time users often emphasize the mast’s resistance to wear and environmental damage. After two seasons, rider Daniel M. said, “My Armstrong Alloy Mast still looks and rides like new. I just rinse it after use and store it properly—no headaches, no rust.”

Such durability translates into lower total ownership costs and less downtime for repairs or replacements.

Community and Customer Support

Beyond the product itself, customers frequently commend Armstrong’s responsive customer service and active community engagement. These factors build trust and loyalty among riders, who feel supported before, during, and after purchase.

Summary of Rider Feedback

| User Group | Key Feedback Highlights |

|---|---|

| Professional Riders | Stability, performance under pressure |

| Beginners | Durability, forgiving flex, confidence boost |

| Long-Term Users | Longevity, minimal maintenance, consistent quality |

| Community | Responsive support, engaged and helpful brand |

Comparison with Competitors: Why the Armstrong Alloy Mast Leads the Pack

Choosing the right mast is crucial for maximizing your foiling experience. The Armstrong Alloy Mast distinguishes itself from competing models through superior materials, manufacturing, and rider-focused design. Here’s why Armstrong stands out.

Premium Material Quality vs. Standard Aluminum

While many competitors use generic aluminum alloys or lower-grade metals, Armstrong employs a carefully selected high-grade aluminum alloy treated with advanced heat processes. This results in superior strength, better corrosion resistance, and a longer lifespan.

In contrast, cheaper competitors may suffer from premature corrosion, fatigue, or structural weakness under similar conditions.

Advanced Manufacturing and Finishing Techniques

Armstrong’s use of CNC machining combined with multi-layer anodizing sets it apart. This precision engineering ensures tight tolerances, enhanced durability, and a sleek finish.

Competitor masts often rely on less refined manufacturing processes, resulting in inconsistencies, surface imperfections, and lower corrosion protection.

Balanced Flex and Stiffness Profile

Unlike some alloy masts that are either too stiff or too flexible, the Armstrong Alloy Mast strikes the perfect balance. This results in improved control and shock absorption, offering a more comfortable ride.

Other brands may prioritize stiffness at the expense of rider comfort or vice versa, limiting versatility.

Compatibility and User Convenience

Armstrong designs the Alloy Mast to fit seamlessly with major foil and board systems, eliminating compatibility headaches. Many competitors produce proprietary mounting systems, forcing riders to purchase specific components or adapters.wing stabilizer

This flexibility makes Armstrong a more cost-effective and user-friendly option.

Customer Support and Warranty

Finally, Armstrong offers responsive customer service and a robust warranty program. This contrasts with some competitors whose support may be slow or limited, potentially leaving customers without assistance when issues arise.wing stabilizer

Quick Comparison Table

| Feature | Armstrong Alloy Mast | Typical Competitor Masts |

|---|---|---|

| Aluminum Quality | High-grade, heat-treated | Generic, untreated alloys |

| Manufacturing | CNC machining, anodizing | Basic machining, limited finishing |

| Flex & Stiffness | Balanced and responsive | Often too stiff or too flexible |

| Mount Compatibility | Standardized, broad | Proprietary, limited |

| Warranty & Support | Responsive and comprehensive | Variable, often limited |

Maintenance and Care for the Armstrong Alloy Mast

Proper maintenance is vital to maximize the lifespan and performance of your Armstrong Alloy Mast. While designed to be durable and corrosion-resistant, regular care ensures it stays in peak condition season after season.wing stabilizer

Rinse with Fresh Water After Every Use

Saltwater and debris can accelerate corrosion and wear, even on anodized alloy surfaces. Therefore, it’s essential to rinse the mast thoroughly with fresh water immediately after each session.

This simple step helps remove salt, sand, and other contaminants that could damage the protective coating or accumulate in mounting areas.

Regular Inspections for Damage

Before and after use, inspect the mast carefully for any cracks, dents, or surface abnormalities. Pay close attention to the mounting points and welds, as these areas experience the most stress.

Early detection of damage allows you to address issues promptly, preventing them from worsening or causing failure during use.

Proper Storage and Handling

Store the mast in a cool, dry place away from direct sunlight to prevent UV degradation of the anodized finish. Using a protective sleeve or case during transport and storage minimizes the risk of scratches and dings.

Avoid leaning the mast against hard surfaces or stacking heavy objects on top, which could cause deformation.

Lubricate Moving Parts and Connectors

If your foil setup includes adjustable or detachable parts, regularly apply a silicone-based lubricant to the connectors and moving components. This practice reduces friction, prevents corrosion, and maintains smooth assembly and disassembly.

Avoid petroleum-based lubricants, as they can degrade aluminum and anodized surfaces.

Follow Armstrong’s Official Care Guidelines

Always consult Armstrong’s official care and maintenance instructions. Following manufacturer recommendations ensures your mast remains within warranty terms and receives proper care.

In case of significant damage or wear, seek professional assessment and repair services authorized by Armstrong.

Maintenance Checklist

-

Rinse thoroughly with fresh water after every use

-

Inspect for cracks, dents, and wear regularly

-

Store in a cool, dry, shaded area with protective casing

-

Lubricate connectors and moving parts with silicone lubricant

-

Adhere to Armstrong’s official care and warranty instructions

wing stabilizer Buying Guide: Selecting the Right Armstrong Alloy Mast for Your Foiling Needs

Choosing the perfect mast can transform your foiling experience. The Armstrong Alloy Mast offers options designed to fit various skill levels, riding styles, and conditions. This buying guide helps you make an informed choice that matches your needs.

Choose the Correct Mast Length

Armstrong provides several mast lengths—commonly 70 cm, 80 cm, and 90 cm. Each length suits different riding scenarios:

-

70 cm: Ideal for beginners or flat water riders, offering stability and easier control.

-

80 cm: Versatile length for intermediate riders or moderate water conditions.

-

90 cm: Preferred by advanced riders who require greater lift and performance in choppy or wave conditions.

Selecting the right length ensures optimal lift, balance, and maneuverability.

wing stabilizer Verify Compatibility with Your Foil and Board

Thanks to standardized mounting systems like Tuttle boxes and plate mounts, the Armstrong Alloy Mast integrates smoothly with most major foil brands and boards.

Nonetheless, confirm your existing setup’s compatibility to avoid needing adapters or modifications.

Consider Your Riding Style

Different riding styles benefit from specific mast features:

-

Freestyle: Shorter masts for agility and rapid response.

-

Racing: Longer, stiffer masts for speed and stability.

-

Cruising: Medium-length masts balancing comfort and performance.

Understanding your style helps narrow your choice.

Factor in Weight and Portability

Though alloy masts are generally heavier than carbon, Armstrong’s design keeps weight manageable. Consider your transport and storage needs, especially if traveling frequently.

Using protective sleeves enhances portability and safeguards your mast.

Budget and Value

Armstrong Alloy Masts offer excellent value, balancing performance and durability at a competitive price point. Investing in quality reduces replacement costs and enhances reliability.

Quick Buying Tips

-

Match mast length to your skill level and typical conditions

-

Confirm mounting compatibility before purchase

-

Select based on your preferred riding style

-

Consider portability for frequent travel

-

Purchase through authorized dealers to ensure authenticity

Frequently Asked Questions (FAQs) About the Armstrong Alloy Mast

Getting clear answers helps you make the most of your Armstrong Alloy Mast. Below are some of the most common questions riders ask, along with detailed responses.

What materials make up the Armstrong Alloy Mast?

The mast is crafted from a high-grade aluminum alloy treated with advanced heat processes and a multi-layer anodized coating. This combination ensures strength, corrosion resistance, and durability.

What sizes are available?

Armstrong offers the Alloy Mast in several lengths, typically 70 cm, 80 cm, and 90 cm, to accommodate different skill levels and riding conditions.

Is the Armstrong Alloy Mast compatible with my foil setup?

Yes. Thanks to standardized mounting interfaces like Tuttle boxes and plate mounts, the mast fits most popular foil and board brands. Always verify your specific equipment compatibility before purchase.

How heavy is the mast?

Depending on length, the mast weighs between approximately 1.8 and 2.4 kilograms, providing a good balance of strength and manageable weight.www.armstrong.com

How should I maintain the Armstrong Alloy Mast?

Rinse with fresh water after use, inspect regularly for damage, store in a dry, shaded area, and lubricate moving parts with silicone-based lubricants. Following Armstrong’s care guidelines ensures long-lasting performance.www.armstrong.com

What warranty comes with the Armstrong Alloy Mast?

Armstrong offers a comprehensive warranty covering manufacturing defects and material failures. Warranty length and terms may vary by region and retailer, so check with authorized sellers.www.armstrong.com

Can I travel with this mast?

Yes. The mast’s durable design and manageable weight make it travel-friendly. Use a protective sleeve or case to prevent damage during transit.

Conclusion: Choose the Armstrong Alloy Mast for Reliability and Performance

The Armstrong Alloy Mast stands out as a durable, versatile, and high-performance choice for foilers of all levels. Combining premium aluminum alloy construction, precision manufacturing, and thoughtful design, it delivers strength and control in every session.www.armstrong.com

Whether you’re a beginner seeking a forgiving mast or an advanced rider demanding reliability in challenging conditions, Armstrong’s Alloy Mast adapts to your needs. Its corrosion resistance and balanced flex ensure longevity and ride comfort, while broad compatibility simplifies upgrades and setups.

Investing in the Armstrong Alloy Mast means trusting a product backed by rigorous quality control, extensive rider feedback, and dedicated customer support.www.armstrong.com

Ready to Elevate Your Foiling Experience?

Explore the Armstrong Alloy Mast today and discover the difference that quality craftsmanship makes. Visit authorized dealers or Armstrong’s official website to find the perfect mast length and accessories for your setup.www.armstrong.com

Don’t settle for less—choose Armstrong and ride with confidence!

Related products

-

Performance Carbon Mast

€850.00 – €1,080.00Price range: €850.00 through €1,080.00Select options This product has multiple variants. The options may be chosen on the product page -

A+ Carbon mast

€520.00 – €600.00Price range: €520.00 through €600.00Select options This product has multiple variants. The options may be chosen on the product page

Reviews

There are no reviews yet.